The Versatility of Sheet Metal Fabrication in Commercial Kitchen Design

11 April 2024

Unveil the transformative power of sheet metal fabrication in Melbourne’s commercial kitchens. Optimise your kitchen with L&C Harding Plumbing. Talk to us!

Efficient and durable design is paramount in commercial kitchens. From high-end restaurants to bustling cafes, these culinary workspaces demand materials that can withstand the rigours of daily operations while seamlessly integrating into the overall design aesthetic. One material that consistently rises to the challenge is sheet metal, a versatile and robust solution that has become an indispensable component in commercial kitchen design.

The Role of Sheet Metal Fabrication in Commercial Kitchen Design

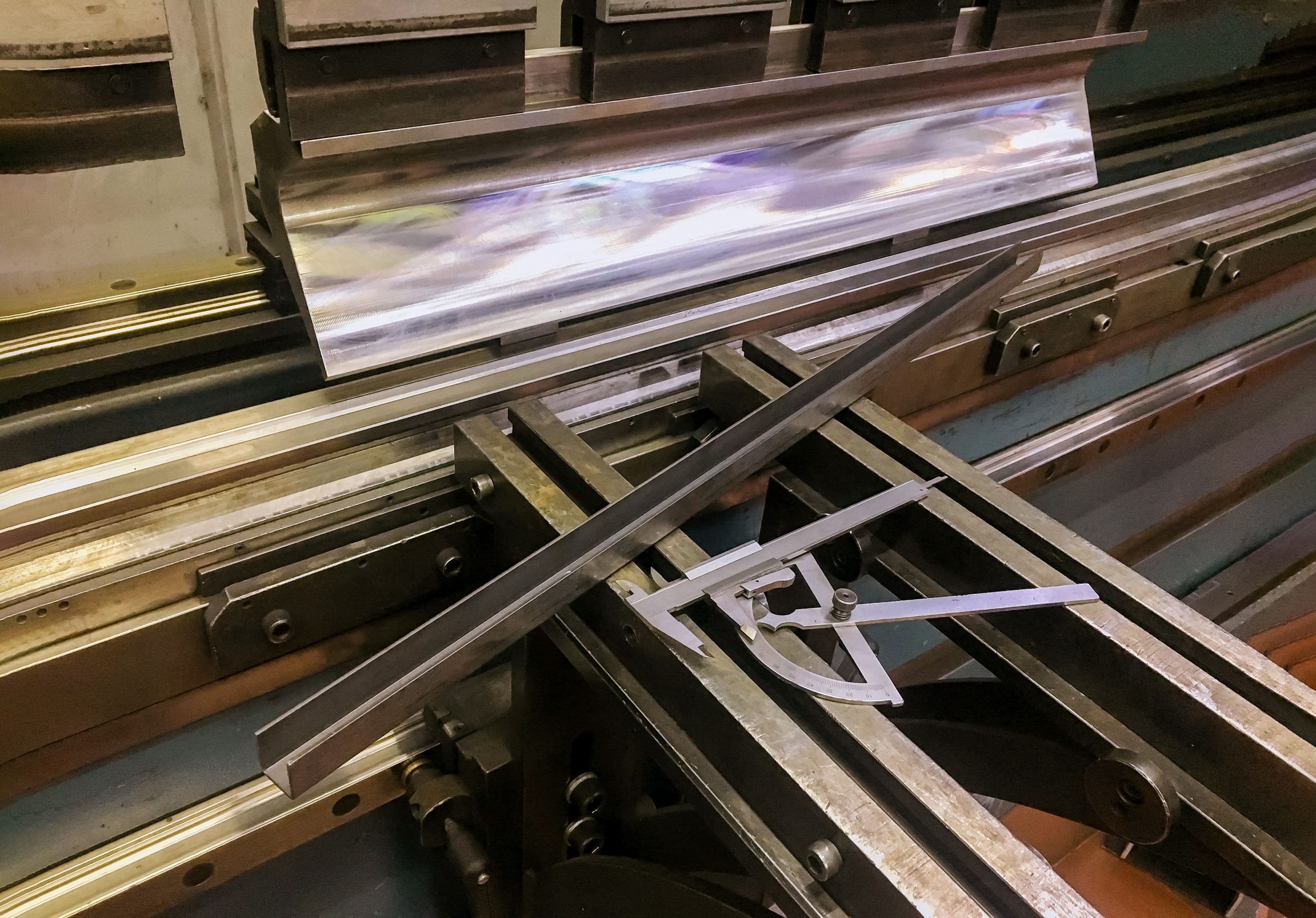

Sheet metal fabrication plays a crucial role in creating functional and visually appealing commercial kitchen spaces. This process involves shaping and manipulating sheets of metal into various components and structures tailored to meet specific design and operational requirements. The resulting products not only enhance the kitchen’s functionality but also contribute to its overall aesthetic appeal, creating a cohesive and professional environment.

Applications of Sheet Metal in Commercial Kitchens

Let’s explore how sheet metal finds its place in various applications within commercial kitchen design.

• Countertops and Work Surfaces – Sheet metal is often used to fabricate countertops and work surfaces in commercial kitchens due to its durability and resistance to heat and moisture. These surfaces provide a hygienic and easy-to-clean workspace for chefs and kitchen staff, ensuring food safety and efficiency.

• Ventilation Systems – Ventilation is essential in commercial kitchens to remove heat, smoke, and cooking odours. Sheet metal fabrication is commonly employed to create ductwork and ventilation systems that efficiently remove air pollutants and maintain a comfortable working environment for kitchen staff.

• Shelving and Storage Units – Sheet metal fabrication allows for the creation of customised shelving and storage units that maximise space and organisation in commercial kitchens. These units are designed to withstand heavy loads and frequent use, providing chefs and kitchen staff with easy access to ingredients, utensils, and equipment.

Considerations for Integrating Sheet Metal in Kitchen Design

Let’s explore key considerations for seamlessly integrating sheet metal into commercial kitchen layouts in Melbourne.

• Hygiene and Food Safety – When integrating sheet metal into kitchen design, it’s essential to prioritise hygiene and food safety. Choosing non-porous and easy-to-clean materials will help prevent bacterial growth and ensure compliance with health and safety regulations.

• Maintenance Requirements – Sheet metal surfaces require regular maintenance to keep them clean and free from corrosion. Designers should consider accessibility and ease of maintenance when incorporating sheet metal into kitchen layouts to minimise downtime and ensure optimal performance.

• Customisation and Flexibility – Each commercial kitchen has unique requirements and space constraints. Designers should work closely with sheet metal fabricators to create customised solutions that meet the specific needs of the kitchen environment, maximising functionality and efficiency.

At L&C Harding Plumbing, our sheet metal fabrication work is carried out to satisfy the customer, meeting your unique specifications and industry needs. We do our best for a quick turnaround if a client needs the job done urgently, ensuring that you can get on with the job you need to do. Trust our expertise to create functional, hygienic, and visually stunning commercial kitchen spaces that stand the test of time.